About Flexy Weld

From Days to Minutes

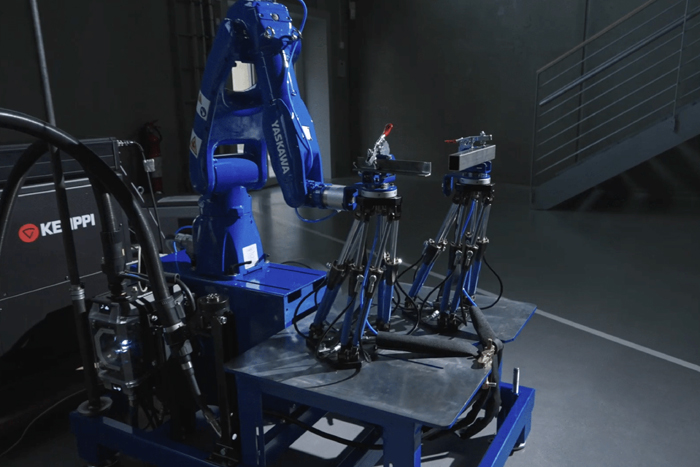

Our hexapod-based robotic welding cell makes it very easy to switch from batch to batch – enabling use of robot for small batch production and thereby larger parts of the entire welding tasks.

Based on your production drawings and simple commands entered into the user interface, the robotic cell is able to create its next production setup.

With the hexapods and tools attached to it a new welding fixture is created in minutes – and you can start on the next welding order.

No need to store physical fixtures, maintain and bring front and back between the orders. All is laying in your database.

Simple to handle, fast to adjust – saving costs, increasing capacity (without having to hire more welding specialists) and while keeping a highly flexible production flow.

Hexapods

Flexible fixture created using our patented hexapods

UI and software

From drawing to coordinates and fixing the robot cell

Tooling and welding equipment

Tooling that enables positioning, gripping and manipulating the objects to be welded in any required way

Hexapods

Our hexapods can be manipulated by the robot arm and fixed in the required positions for it with the attached holding tool to hold the metal pieces to be welded.

These patented Hexapods are the mechanical solution, possible to use for any size, weight, and shape of production parts to be welded.

Stability and high performance based on a pressure controlled system – providing accuracy and repeatability – 0,01 mm.

UI and software

The Flexy Weld User Interface is made to ease the process of converting the digital drawings to 3D Data and positioning of hexapods – providing the next setup/fixture.

The data is used by the robot arm, that in practice does the positioning of the hexapods.

Once a program is made it is saved and can anytime be selected from the program library. Enabling shift between production orders in a matter of a few minutes.

In simulation mode the full process can be monitored before use – and adjustments and optimizations are easily done if need be.

Tooling and welding equipment

Quick reconfiguration of the Hexapods to adapt to the new welding order includes the option to change the tooling attached to the hexapods manually/automatically.

On the top of the hexapods are mounted clamping devices and tool adaptors.

To ensure the high-quality welding the robot cell is equipped with Kemppi welding guns – fully adapted to our cell and its performance.

The cell includes safety fence and welding tables – all to make the mechanical performance excellent.